For many decades, Lean Six Sigma has become one of the most widely adopted improvement strategies across various industries due to its capability in achieving enhanced quality, efficiency, and profitability while boosting productivity and attaining continuous improvement.

However, is it still relevant today when Agile, AI, and Big Data are taking the business world by storm in such a short time?

The answer – Absolutely!

Despite the criticisms aimed at Lean Six Sigma (LSS) caused by its limitations, such as lack of data, long implementation cycles, and ineffective deployment strategy/roadmap [1], Lean Six Sigma is still being deployed by many organizations across various industries worldwide, even in the current age of digital transformation. In fact, this methodology is so versatile and flexible that it is evolving rapidly through integrations with modern digital tools from Industry 4.0; thus, furthering its capabilities and countering its limitations. These tools, like Artificial Intelligence (AI), can greatly expand and facilitate LSS projects and enhance their benefits [1]. This integration is what is called “LSS 4.0”.

LEAN SIX SIGMA

Lean Six Sigma (shortened to LSS) is the synergy of Lean Manufacturing and Six Sigma Management principles. Lean focuses on streamlining processes by eliminating waste, whereas Six Sigma aims to enhance quality by reducing variations. Hence, when combined, LSS becomes a powerful methodology that helps organizations continuously improve business operations and enhance customer satisfaction [2, 3, 4].

This well-established methodology encompasses tools and techniques that aim at quality enhancement, process improvement, cost reduction, and operational excellence within an organization [5, 4]. For instance, Fishbone Diagram, 5 Whys, FMEA, Root Cause Analysis (RCA), Poka Yoke, Kanban, 5S, and Value Stream Mapping (VSM) – to name a few. But one of the most popular and critical tools of Lean Six Sigma is the widely known “DMAIC Framework”.

WHAT IS DMAIC?

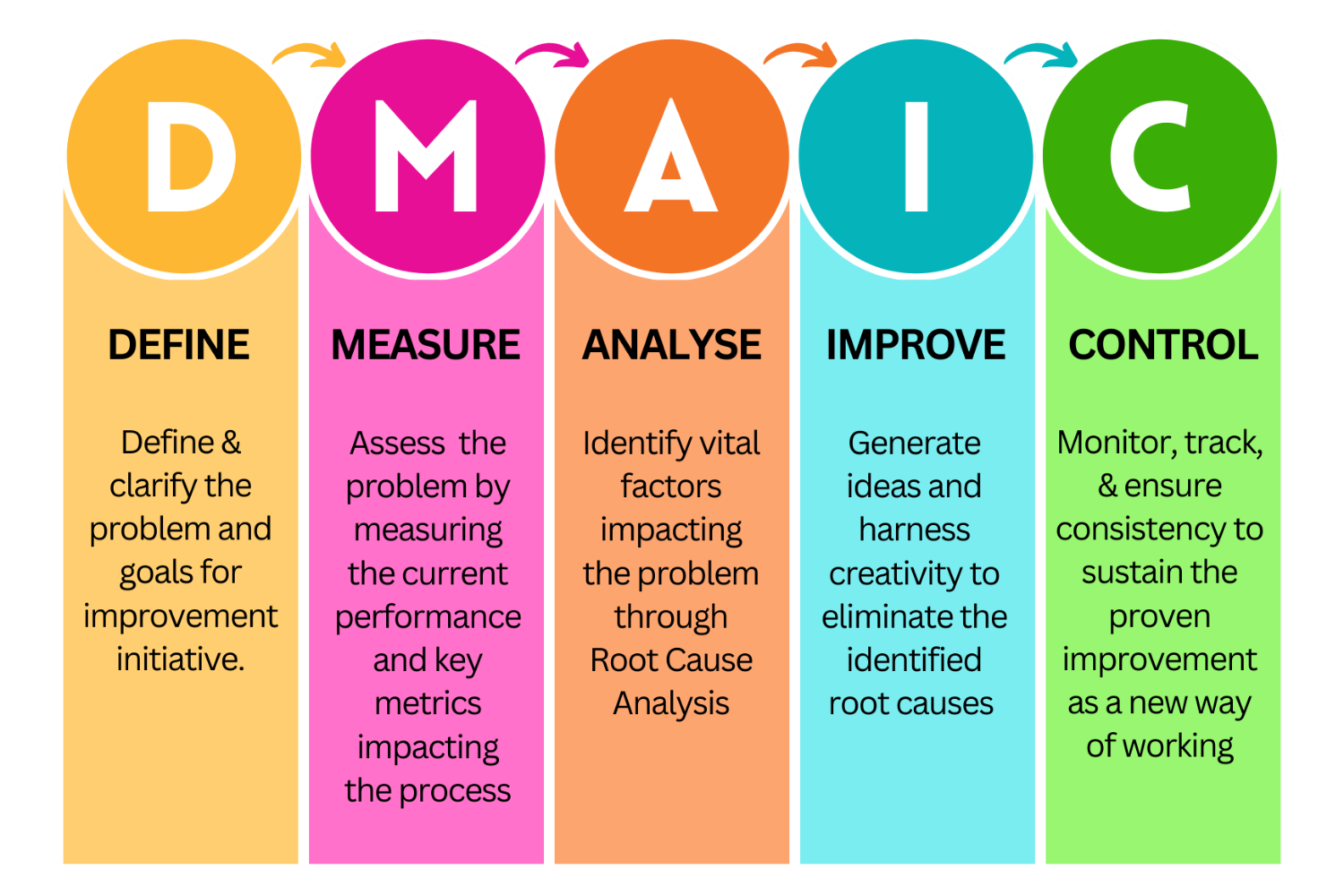

DMAIC is a problem-solving and quality management methodology used in Lean Six Sigma projects. DMAIC stands for Define, Measure, Analyze, Improve, and Control. As outlined here, it provides a structured framework that aims to identify and quantify sources of variation to improve existing processes and achieve operational excellence and continuous improvement [6, 7, 8, 9, 10, 5]. At each stage of this powerful framework, it brings together suitable Lean and Six Sigma tools and techniques to facilitate data-driven decision-making and develop an effective deployment model, catering to organizations with diverse needs [10].

DMAIC initially serves as a fundamental framework within the Six Sigma methodology. By combining Lean Principles, waste and inefficiencies can be tackled thoroughly by pinpointing the root causes of the waste and streamlining processes to deliver sustainable results and improve quality [10].

On top of that, not only is DMAIC a widely recognized methodology for quality management and process improvement, but it is also formally standardized in ISO 13053, the international standard for Six Sigma methodologies. In ISO 13053, DMAIC is outlined as the primary structured method for process improvement. With its clear step-by-step framework, the standard ensures that organizations follow a systematic roadmap to achieve sustainable results. ISO 13053 reinforces DMAIC’s credibility, which provides a benchmark in helping organizations implement best practices across projects.

To illustrate, each stage plays different and equally crucial roles and responsibilities, which are [2, 4];

- DEFINE – Clearly define and clarify the project scope, goals, and expected outcomes. This includes selecting the project, establishing objectives, timelines, and conditions for success, as well as appointing a project leader and team members, and identifying stakeholders. A well-defined problem statement and project charter are created to ensure alignment.

- MEASURE – Collect data to understand the current state of the process. Key process inputs, outputs, and performance indicators are evaluated to make the problem quantifiable and measurable. Measurement systems are validated to ensure accuracy, and baseline performance is established to serve as a benchmark for future improvements.

- ANALYZE – Examine data to identify the root causes of waste, defects, and inefficiencies using statistical analysis and tools. This stage includes diagnosing the current situation, testing hypotheses, and pinpointing the factors that contribute to the problem.

- IMPROVE – Generate and execute solutions to address the identified issues. This involves designing new processes or improving existing ones, piloting changes, and applying Lean techniques to eliminate waste. The aim in this stage is to optimize performance, reduce variation, and generate measurable benefits in cost, quality, and efficiency.

- CONTROL – Establish a control system to ensure that the improvements are sustained long-term. This includes standardized processes, monitoring systems, and a control plan. Besides that, having clear documentation, training, and handover to process owners ensures that the gains are embedded, whereas dashboards and statistical process control (SPC) facilitate result tracking after project closure.

DMAIC (Source: Author’s own work)

WHY DMAIC STILL WORKS

Business owners who seek to improve their operations, cut costs, enhance product/service quality, and meet customer needs tend to turn to problem-solving and process improvement approaches like Lean Six Sigma and deploy DMAIC-based initiatives [5].

However, the problem with Lean Six Sigma and DMAIC in the past was their reliance on manual data collection, retrospective analysis, and reactive decision-making. These aspects limit their effectiveness within complex environments [11].

Granted, now that technological connectivity has arisen exponentially throughout the world and access to massive data has become easier, LSS has advanced in line with the digital evolution. The potential of a robust integration between LSS’s DMAIC framework and IR4.0 advanced tools in operations and processes shows great promise, given DMAIC’s versatility in adapting to diverse techniques and tools [4].

Ultimately, it augments and redefinesLean Six Sigma DMAIC as we know it.

So, yes, DMAIC still works!

With the integration of IR4.0 tools such as Artificial Intelligence (AI), Big Data, Internet of Thing (IoT), cloud computing, machine learning, and the like, DMAIC’s effectiveness can be elevated – faster, accurate, and sustainable.

Let’s refresh our memories on how DMAIC deployment can positively impact organizations across various industries, in general:

Structured and Systematic Approach

- DMAIC provides a clear framework for problem-solving initiatives, from start to finish, using an analytical approach to identify and deliver sustainable solutions and achieve bottom-line results [12, 13, 14, 15]Its systematic structure ensures consistency and clarity across projects, which facilitates process documentation, staff training, and knowledge sharing [16, 17]

- Plus, DMAIC’s structure ensures that all initiatives begin with analysis before solution execution, thus reducing the risk of addressing the wrong issue [18].

Data-Driven Decision-Making

- By collecting and analyzing quantifiable data, DMAIC provides accurate baselines, which in turn can help project teams track progress, identify root causes, and make data-driven decisions in developing quality improvements even for complex issues [15, 18, 14, 17].DMAIC utilizes advanced data analysis tools and techniques (e.g., Fishbone Diagram, 5 Whys) that greatly help in identifying the true root causes of problems, instead of symptoms, and prevent problems from recurring as well as ensuring solutions are sustainable [17].

- As DMAIC’s foundation lies in its statistical data-driven approach, it minimizes bias and provides objectivity that leads to more accurate and reliable results [12, 17].

Focus on Customer Needs

- DMAIC focuses on customer needs to enhance customer satisfaction. It ensures alignment of its initiatives with customer requirements by improving product and service quality [12, 15].

- Using Voice of Customer (VoC) and Kano Analysis within its Define phase, DMAIC helps organizations gain customer loyalty and define better products/services to meet customer expectations [15, 19].

Continuous Improvement and Sustainability

- What makes DMAIC one of the most effective problem-solving methodologies is how its Control phase is set to establish a control system (control plans, audits, performance monitoring, etc.) to sustain improvements [17].

- This system encourages teams to consistently refine processes over time, ultimately fostering a culture of continuous improvement within an organization [20]

Collaboration and Team Engagement

- DMAIC-based Lean Six Sigma improvement projects, especially large-scale and complex ones, are commonly executed by teams across different departments with diverse expertise and perspectives [17]. DMAIC’s structured framework and common language facilitate robust collaboration among team members of different expertise in aligning their efforts [12].

- Cross-functional collaboration helps build team coordination and effective communication through knowledge sharing that can help reach a better understanding of the issue and determine the best solutions in pursuit of a common goal [12, 18]. This in turn creates a more vibrant work environment [15, 18].

- In this regard, the enhanced clarity, collaboration, and alignment increase commitment and accountability over the project among all stakeholders [17].

Flexibility and Scalability

- The methodology can not only be adapted to both small and large, complex projects, but also in implementing a large range of different tools and techniques required for the project [21, 4]. As such, it provides a functional method for achieving higher impact process improvements [21, 18].

- DMAIC is highly flexible in its deployment across organizations in any industry, as its focus lies primarily on the processes within the organization [1].

- Being a structured, top-down approach, its straightforward framework allows equal participation among employees of all levels, regardless of the complexity of the project [18].

- DMAIC accelerates improvement cycles by streamlining communication, visibility, and responsibilities, reducing downtime between phases [20, 14].

DIGITAL TRANSFORMATION

Faster. Easier. Cheaper. All customers want these, and digital transformation is the way to meet these expectations.

The competition among companies worldwide in adopting digital transformation is intensifying more than ever. With today’s rapid technological evolution and constant innovation, it has become crucial for organizations to not only remain competitive but also stay ahead of the digital curve – lest they become obsolete in the business market [4].

Air Asia, Agoda, Grab, Netflix, and Shopee are just a few of the many companies that have successfully embraced digital transformation, greatly transforming their businesses [26, 27, 28, 29, 30, 31, 32].

In layman’s terms, digital transformation is basically the use of modern technology within business operations to make work faster, easier, and done correctly. It transforms one’s business operations, processes, and culture into one that meets customer needs and remains relevant to the current market. from increased automation, data collection, and data-driven insights to cost savings, greater efficiency and productivity, and improved innovation and competitiveness [4, 22, 23] – simply put, digital transformation is the future of business.

DIGITAL TRANSFORMATION & INDUSTRY 4.0

In the context of manufacturing and production industries, digital transformation takes form through “Industry 4.0” – a.k.a. the Fourth Industrial Revolution (4IR) – where advanced technologies (i.e., AI, Machine Learning, Digital Twins, IoT, Big Data, RPA, etc.) are used to allow real-time decision-making, automated processing, and enhanced productivity, flexibility, and agility throughout an organization. This modernization and digitalization of processes will ultimately revolutionize the way companies manufacture, improve, and distribute their products [23, 24]

LSS DMAIC & INDUSTRY 4.0

Lean Six Sigma is a proven solution for businesses seeking to improve their quality, productivity, and process efficiency [5]. As long as there is a process, any industry can employ LSS.

Now, while LSS has its limitations, such as poor data analysis, a lack of data collection capabilities, and time-consuming initiatives, utilizing Industry 4.0 can exponentially compensate for them. For instance, [1] described the opportunities to address these limitations, such as installing sensors and cameras to record and store large amounts of data across various parameters, thereby ensuring high data volume and quality. Then, having these devices interconnected through an automated network enables faster and more accurate data collection with fewer errors compared to traditional manual methods. Plus, with an automated data collection and reporting system – like one being powered by AI – data can be processed and reported in real-time, which leads to faster identification of trends and results. With this automation and accurate analysis, LSS initiatives can be implemented with less time required.

This integration, commonly referred to as LSS 4.0, combines Industry 4.0 technologies with LSS’s structured methodology, DMAIC, to enhance and expand its capabilities in driving operational excellence [10]. With the advancement of science and technology, [2] believed that Industry 4.0 tools are now increasingly adopted to complement Lean practices. Rather than creating a conflict, these technologies can instead amplify them – increasing flexibility, productivity, and responsiveness that align better with market demands.

In addition, [6] described how AI, in particular, has shown itself to be a natural partner to Six Sigma, since both rely heavily on data analysis and continuous improvement. Evidently, with its foundation in mathematics and statistics, Six Sigma provides a clear structure for solving complex problems. Whereas AI accelerates these processes through trend and pattern detection that are often undetectable to manual analysis. This makes AI an ideal complement to the DMAIC framework, automating tasks such as root cause identification, predictive maintenance, and error detection, thereby speeding up problem-solving and reducing human error, wastage, and cost [6, 9, 5].

The synergy of AI and LSS DMAIC framework provides opportunities to achieve process optimization at a faster and higher success rate [9]. AI’s capabilities in prediction, trend identification, and machine learning can elevate each DMAIC phase, from defining and measuring problems with higher accuracy, to analysing data faster, and thereby improving processes through simulation and controlling outcomes through proactive monitoring [1, 6, 9].

Thus, these technologies can enhance Lean Six Sigma beyond its conventional boundaries. AI and other Industry 4.0’s digital capabilities can definitely transform DMAIC into a powerful method that ensures higher productivity and quality standards, and long-term sustainability and innovation across industries, leading to continuous improvement [9]. As such, this upgrade enables organizations to overcome the limitations within the traditional LSS DMAIC approach [9].

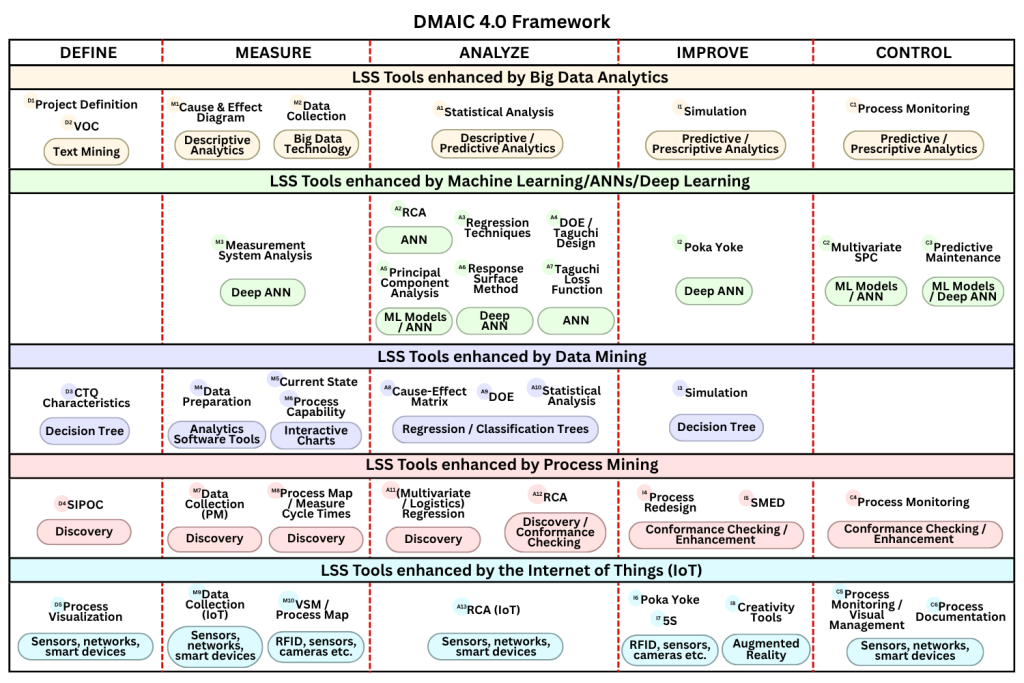

What’s more, [1] provides an extensive study that demonstrates the development of DMAIC 4.0, which entails the integration of Lean Six Sigma with Industry 4.0 technologies into the DMAIC phases. This enhanced Lean Six Sigma model is designed to address common limitations of the traditional LSS (i.e., manual data collection, challenges to sustain improvements, etc.) through the introduction of 42 enriched tasks supported by digital tools. Using action research in a German manufacturing company for validation of its effectiveness, and further confirmed by a Delphi study, the model demonstrated both theoretical and practical contributions. This made DMAIC 4.0 a robust methodology capable of driving operational excellence in the era of digital transformation.

DMAIC 4.0 Framework (referred & modified from [1])

MODERN APPLICATION OF DMAIC

Here are some case studies of how DMAIC and Industry 4.0 are incorporated to help businesses achieve their goals:

- In a 2024 study, [10] deployed Lean Six Sigma 4.0 to optimize the process of occupational exams in a Brazilian company. Through the DMAIC framework, they combined LSS tools (i.e., Pareto analysis, Ishikawa Diagram, and BPMN mapping) with digital technologies (i.e., Minitab and process monitoring). The project successfully reduced inefficiencies and unnecessary costs due to a surge in medical exams. This shows that DMAIC can be enhanced using advanced digital tools and address modern operational challenges more effectively.

- [2] studies how LSS DMAIC combined with Robotic Process Automation (RPA) can radically improve the medical expense claim review process of a Taiwanese hospital under Taiwan’s National Health Insurance System. Due to changes in policy and complex claim rules, inefficiencies and manual labour had substantially increased. By deploying DMAIC phases, the team was able to identify NVA and wasteful activities, and replace manual, repetitive tasks with RPA. This initiative resulted in a 380-minute decrease in the process time and raised Process Cycle Efficiency (PCE) from approximately 69.07% to 95.54%. Besides that, this effort allows staff to focus on more value-adding tasks and creative work that are more patient-centric.

- A study by [25] demonstrated the application of a simulation-based LSS approach in a process industry. Using DMAIC, the project combined Minitab’s statistical tools, MATLAB/Simulink simulations, and Taguchi-grey relational analysis to address variability in a Reverse Osmosis water purification process. Simulation and real-time data analysis were utilized to construct different process scenarios, virtually optimize control parameters, and validate improvements before physical implementation. Results show that the integration has led to an increase in Sigma level from 1.14 to 3.88, a 56% decrease in variation, a 22% increase in mean performance, and annual savings equivalent to 20% of production costs. This study demonstrates how compatible digital tools are with DMAIC, making it more recognized as a robust and adaptable methodology.

- In 2020, [4] explored how digital transformation can be incorporated into LSS supply chain projects using a tailored DMAIC framework. Sampling three case studies, they demonstrated how Industry 4.0 advanced tools like Big Data and digital connectivity can enhance visibility, cycle times, and quality performance across supply chains. As such, their proposed framework provides companies with a clear, practical guide on how to integrate digital tools into each DMAIC stage. This offers flexibility for organizations at different stages of digital maturity. Essentially, this paper provides a good example of how digital transformation combined with LSS can help organizations achieve system-wide supply chain gains on top of specific process improvements.

As organizations across industries traverse the era of digital transformation, Lean Six Sigma DMAIC’s relevance remains undeniable. Even when industries adopt advanced technologies, DMAIC’s systematic, data-driven practice provides clarity, discipline, and quantifiable results. Rather than being replaced, DMAIC proves that it has evolved and can integrate seamlessly with today’s newest technology and enhance each phase’s capabilities.

From simple to complex environments, this integration (often referred to as LSS 4.0) provides organizations with a powerful and future-ready guide that can significantly accelerate their efforts in operational excellence in the digital age.

Need training or expert consultation in process improvement?

Then, come and enroll in our Lean Six Sigma training now to master methodologies and techniques that drive profitability through waste elimination, quality management, and continuous improvement!

We offer flexible training modes: public training, in-house training, and online training – choose the one that best suits your needs.

If you’re for hands-on Lean Six Sigma consultation, then we have your back! We also provide expert guidance in Root Cause Analysis and Value Stream Mapping training, Capability Development Programmes (CDP), and Lean & Quality Management projects – covering project selection, coaching, tollgate reviews, and audits to ensure successful implementation and measurable results.

Take the next step towards operational excellence – contact us today!

BE A MEMBER TODAY!

Join us and become a member to receive various membership perks – vouchers, discounts, networking, and more! Visit us at https://sixsigma.org.my/membership/ for more information.

Looking forward to having you onboard!

REFERENCES

[1] T. Pongboonchai-Empl et al., “DMAIC 4.0 – innovating the Lean Six Sigma methodology with industry 4.0 technologies,” Production Planning and Control, pp. 1–22, Mar. 2025. doi:10.1080/09537287.2025.2477724

[2] W.-L. Huang et al., “A case study of Lean digital transformation through robotic process automation in Healthcare,” Scientific Reports, vol. 14, no. 1, Jun. 2024. doi:10.1038/s41598-024-65715-9

[3] B. Lameijer, E. S. L. de Vries, J. Antony, J. A. Garza-Reyes, and M. Sony, “The implementation of lean six sigma for the optimization of robotic process automation systems in financial service operations,” Business Process Management Journal, vol. 30, no. 8, pp. 232–259, Jul. 2024. doi:10.1108/bpmj-08-2023-0640

[4] H. L. Tay and H. S. Loh, “Digital transformations and Supply Chain Management: A Lean Six Sigma perspective,” Journal of Asia Business Studies, vol. 16, no. 2, pp. 340–353, Jun. 2021. doi:10.1108/jabs-10-2020-0415

[5] S. Goyal, H. Jha, and A. Gupta, “Prediction in Industry 4.0 with Lean Six Sigma,” Lecture Notes in Networks and Systems, pp. 569–575, 2023. doi:10.1007/978-981-19-6088-8_51

[6] S. M. S. Bukhari and R. Akhtar, “Leveraging artificial intelligence to revolutionize Six Sigma: Enhancing process optimization and predictive quality control,” Contemporary Journal of Social Science Review, vol. 2, no. 4, pp. 1932–1948, 2024.

[7] A. Ibrahim and G. Kumar, “Selection of Industry 4.0 Technologies for Lean Six Sigma integration using fuzzy DEMATEL approach,” International Journal of Lean Six Sigma, vol. 15, no. 5, pp. 1025–1042, Jan. 2024. doi:10.1108/ijlss-05-2023-0090

[8] T. Pongboonchai-Empl, J. Antony, J. A. Garza-Reyes, T. Komkowski, and G. L. Tortorella, “Integration of Industry 4.0 Technologies into Lean Six Sigma DMAIC: A systematic review,” Production Planning & Control, vol. 35, no. 12, pp. 1403–1428, Mar. 2023. doi:10.1080/09537287.2023.2188496

[9] A. C. Sood and K. S. Dhull, “The future of Six sigma- integrating AI for Continuous Improvement,” International Journal of Innovative Research in Engineering and Management, vol. 11, no. 5, pp. 8–15, Oct. 2024. doi:10.55524/ijirem.2024.11.5.2

[10] T. da Moreira, D. L. Nascimento, Y. Smirnova, and A. C. Santos, “Lean Six sigma 4.0 methodology for optimizing occupational exams in Operations Management,” International Journal of Lean Six Sigma, vol. 15, no. 8, pp. 93–119, Apr. 2024. doi:10.1108/ijlss-07-2023-0123

[11] A. H. Gomaa, “LSS 4.0: A conceptual framework for integrating Lean Six Sigma and Industry 4.0 for smart manufacturing excellence,” Indian Journal of Management and Language, vol. 5, no. 1, pp. 8–29, Apr. 2025. doi:10.54105/ijml.h1810.05010425

[12] L. Kinney, “Driving process excellence: Harnessing the power of DMAIC for Effective Improvement,” isixsigma.com, https://www.isixsigma.com/dictionary/define-measure-analyze-improve-control-dmaic/ (accessed Sep. 29, 2025).

[13] D. Clifford, “Benefits of implementing DMAIC methodology in Project Management,” Medium, https://medium.com/smart-project-kit/benefits-of-implementing-dmaic-methodology-in-project-management-9de917d262c8 (accessed Sep. 29, 2025).

[14] B. Keita, “Understanding the DMAIC methodology: Key insights,” Invensis Learning Blog, https://www.invensislearning.com/blog/an-ultimate-guide-to-dmaic-methodology/ (accessed Sep. 29, 2025).

[15] Safety Culture Content Team, “DMAIC: A Six Sigma tool for business success,” SafetyCulture, https://safetyculture.com/topics/dmaic (accessed Sep. 29, 2025).

[16] S. Tanner, “DMAIC process: The 5 phases of Lean sigma,” Simplilearn.com, https://www.simplilearn.com/dmaic-process-article (accessed Sep. 29, 2025).

[17] G. Lubbe, “DMAIC process: What it is and why it works,” KPI Fire, https://www.kpifire.com/blog/dmaic-process/ (accessed Sep. 29, 2025).

[18] “DMAIC: Approach to continuous improvement,” SixSigma.us, https://www.6sigma.us/dmaic-process/ (accessed Sep. 29, 2025).

[19] S. Ü. Fırat, M. Ö. A. Akan, E. Ersoy, S. Gök, and U. Ünal, “A Six sigma DMAIC process for supplier performance evaluation using AHP and Kano’s model,” International Journal of Business Analytics, vol. 4, no. 2, pp. 37–61, Apr. 2017. doi:10.4018/ijban.2017040103

[20] I. Krasteva, “What is DMAIC?,” Kanban Software for Agile Project Management, https://businessmap.io/lean-management/six-sigma/dmaic (accessed Sep. 29, 2025).

[21] “DMAIC vs PDCA in Six sigma. what should you pick and why,” SixSigma.us, https://www.6sigma.us/process-improvement/dmaic-vs-pdca/ (accessed Sep. 29, 2025).

[22] K. O’Brien, A. Downie, and M. Scapicchio, “What is Digital Transformation?,” IBM, https://www.ibm.com/think/topics/digital-transformation (accessed Sep. 29, 2025).

[23] “What is Digital Transformation?,” McKinsey & Company, https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-is-digital-transformation (accessed Sep. 29, 2025).

[24] “What is Industry 4.0 and how does it work?,” IBM, https://www.ibm.com/think/topics/industry-4-0 (accessed Sep. 29, 2025).

[25] V. S. Bhat, S. Bhat, and E. V. Gijo, “Simulation-based Lean Six Sigma for Industry 4.0: An action research in the process industry,” International Journal of Quality & Reliability Management, vol. 38, no. 5, pp. 1215–1245, Nov. 2020. doi:10.1108/ijqrm-05-2020-0167

[26] “Successful Digital Transformation Underpins AirAsia’s sustainability achievements,” AirAsia Newsroom, https://newsroom.airasia.com/news/successful-digital-transformation-underpins-airasias-sustainability-achievements (accessed Oct. 2, 2025).

[27] A. Semenov and E. Snesar, “Beyond the runway: How AirAsia transformed into a digital lifestyle ecosystem,” https://www.heyinnovations.com/, https://www.heyinnovations.com/resources/airasia-ecosystem (accessed Oct. 2, 2025).

[28] Agoda Careers, “Digital Transformation in Travel: How Agoda is Shaping the Future,” careersatagoda.com, https://careersatagoda.com/blog/tech/digital-transformation-in-travel-how-agoda-is-shaping-the-future/ (accessed Oct. 2, 2025).

[29] A. Macarayan, “How grab’s cloud strategy opened new Innovation Routes,” Frontier Enterprise, https://www.frontier-enterprise.com/how-grabs-cloud-strategy-opened-new-innovation-routes/ (accessed Oct. 2, 2025).

[30] “Grab launches First Artificial Intelligence Centre of excellence with support from Digital Industry Singapore: Grab SG,” Grab, https://www.grab.com/sg/press/others/grab-launches-first-artificial-intelligence-centre-of-excellence-with-support-from-digital-industry-singapore/ (accessed Oct. 2, 2025).

[31] A. Saxena, “How digital transformation propelled Netflix to Eminence,” Appventurez, https://www.appventurez.com/blog/digital-transformation-netflix (accessed Oct. 2, 2025).

[32] “How shopee is winning over shoppers with content, AI and speed,” CNA, https://www.channelnewsasia.com/advertorial/how-shopee-winning-over-shoppers-content-ai-and-speed-5099771 (accessed Oct. 2, 2025).